Common types of iron ore are magnetite, hematite, limonite and siderite. Among them, hematite, as a weak magnetic iron ore, has uneven particle size and high content of fine particles. Hematite ore is an important iron ore resource in my country. In the early 1960s, hematite ore was mainly processed by roasting-magnetic separation and single-flotation processes, and the production technical indicators were poor. After continuous transformation, although the indicators have improved. In recent years, the successful development and application of some new beneficiation techniques, new magnetic separation equipment and new agents have made a major breakthrough in hematite beneficiation technology.

Hematite, also known as red ore, whose chemical formula is ferric oxide(Fe2O3), is a weakly magnetic iron mineral with better floatability than magnetite, and is one of the main raw materials for iron making. Its crystals are oxide minerals of hexagonal crystal system, and the mineral form is mainly iron oxide. According to the composition, it can be divided into four varieties of hematite, including titanium hematite, aluminum hematite, magnesium hematite and water hematite.

Hematite is widely distributed and involves many kinds of minerals, so the beneficiation methods are not single, mainly including the flotation method, magnetic separation method, gravity separation method and roasting magnetic separation method.

1. flotation separation

The flotation method is mainly used to separate fine-grained and particulate weak magnetic hematite ore, including two processes: positive flotation (positive flotation with anionic collectors) and reverse flotation (reverse flotation with cationic collectors). Commonly used collectors include animal and vegetable fatty acids (soap), oxidized paraffin soap, crude tar oil, chlorinated acid, oxidized kerosene, sodium petroleum sulfonate, corn starch, etc.

- Positive flotation: Hematite positive flotation is a method of using anionic collectors to float iron minerals from raw ore. The flotation method is simple in medicine and low in processing cost, and is especially suitable for single hematite ore. However, it takes several selections to obtain qualified hematite concentrate, and the foam is easy to stick, making the product difficult to concentrate and filter.

- Reverse flotation: Hematite reverse flotation is a method of using anionic or cationic collectors to float gangue minerals from raw ore. The reverse flotation of anionic collectors is mostly used when the pH value is 8-9. It is used to treat minerals containing quartz gangue. After activation by calcium ions, reverse flotation is carried out with fatty acid collectors to obtain hematite concentrate. Cationic collector reverse flotation, the flotation agent used at this time is amine collector, which is suitable for flotation of quartz gangue. The amine collector is ether amine as the first choice, followed by aliphatic amine. The inhibitor of iron ore adopts water glass, tannin and sodium lignosulfonate, and the inhibitory effect is the best when the pH value is 8-9.

From the ore properties of hematite itself, reverse flotation has more advantages than positive flotation. Because the object collected by the reverse flotation process is gangue, and the object collected by the positive flotation process is iron minerals. Therefore, it is difficult to obtain high-quality hematite concentrate for minerals with serious inclusion of gangue minerals.

2. Magnetic separation

The weak magnetic-strong magnetic separation method is mostly used for the treatment of magnetite-hematite mixed ore. After the weak magnetic separation tailings are concentrated, strong magnetic roughing and sweeping are carried out, and the strong magnetic rough concentrate is concentrated and selected by a strong magnetic separator. Due to the strong magnetic minerals in a small amount of magnetite in the ore, it is easy to cause the blockage of the strong magnetic field magnetic separator. Therefore, when the strong magnetic separation process is used, a weak magnetic separation operation is usually added before the strong magnetic separation operation to remove or sort out the ore. strong magnetic minerals.

The beneficiation mainly uses a strong magnetic separation process. The magnetic field of magnetic separation is required to be above 10,000 gauss, which can be slightly reduced in dry magnetic separation operations. For some earthy hematites and when fine grinding operations are required, a stronger magnetic field may be required. When the gangue mineral is a silicate mineral with high iron content, the magnetic field strength should not be too strong, so as to avoid lowering the concentrate grade.

3. gravity separation

There are two main types of hematite gravity separation methods: coarse-grain gravity separation and fine-grain gravity separation:

- Coarse-grain gravity separation: the geological grade of the deposit is high (about 50%), but the ore body is thin or there are many interlayers, and the waste rock is mixed in during mining to deplete the ore. For this type of ore, only crushing and no grinding can be used. In the case of coarse particle size, the coarse tailings are discarded through the gravity separation process to restore the geological grade.

- Fine-grain gravity separation: this method is mostly used to treat hematite with fine embedded particle size and high magnetic content. After crushing, the ore is ground to achieve monomer separation of the minerals, and then the fine-grained high-grade concentrate is obtained through the gravity separation process.

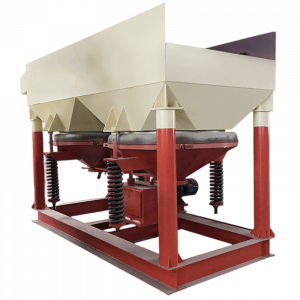

However, due to the low grade of strong magnetic separation concentrate of most weak magnetic iron ores, and the low unit processing capacity of gravity separation process, the combined process of strong magnetic separation and gravity separation is often used. That is, the strong magnetic separation process is used to discard a large number of unqualified tailings, and then the gravity separation process is used to further process the strong magnetic concentrate to improve the concentrate grade. The gravity separation of hematite mainly includes jig beneficiation of coarse-grained hematite, centrifugal beneficiation of fine-grained hematite, and spiral beneficiation and shaking table for medium-grained hematite.

4. Roasting Magnetic Separation

When the mineral composition is complex and other beneficiation methods are difficult to obtain good separation indicators, the roasting magnetic separation process is often used to separate hematite. Mainly, the ore is magnetized and roasted to convert hematite or false hematite into magnetite, which is then separated by a weak magnetic field magnetic separator.

In order to further improve the grade of hematite concentrate, fine screen regrinding and re-selection (which can increase the concentrate grade to more than 65%), regrinding and reverse flotation (which can increase the concentrate grade to 66%) are often used in production. The process further processes the hematite concentrate obtained by magnetic separation.

The above are the common beneficiation methods of hematite. The final determination of the hematite beneficiation process should be comprehensively determined according to the mineral properties and environment, the grade requirements of the final product, and the investment capacity of beneficiation. For general small and medium mines and beneficiation, it is more appropriate to use magnetic separation and gravity separation. For hematite beneficiation, it is suggested that it is best to tailor your own technological process through beneficiation tests.