With the mining of mines and the continuous development of the iron and steel industry, iron tailings, as a kind of beneficiation waste, are also increasing in storage. Iron tailings are solid wastes discharged after extracting iron ore concentrate from iron ore. It is a low-content valuable element produced during the processing and utilization of iron ore. It is one of the important components of mine solid waste.

The general idea of the overall comprehensive utilization of tailings is as follows:

- On the basis of comprehensive physicochemical analysis of iron tailings, re-selection of iron tailings with re-selection and utilization value;

- Use the re-selected iron tailings for simple processing as building materials (iron tailings to make bricks) or use tailings to fill the goaf;

- Finishing the tailings to produce building decoration materials with high added value;

- Carry out ecological restoration and reconstruction of iron tailings that cannot be used temporarily as ecological restoration materials.

1. Iron tailings reselection and comprehensive recovery of valuable elements

Tailings reselection or recovery of valuable elements is one of the main and preferred measures for the overall comprehensive utilization of tailings, including the reuse of old tailings and the reselection of newly generated tailings. Tailings reselection can not only reduce tailings dam construction and maintenance costs, save grinding, mining, transportation and other costs, but also save greater investment in equipment and new process development, so it has received more and more attention.

Especially since the 1990s, some mining enterprises in my country have successively built some iron tailings recycling and dressing plants in consideration of improving economic benefits, and achieved obvious economic benefits. For example, Maanshan Iron and Steel Nanshan Iron Mine Aoshan Iron Concentrator produces 40,000 tons of tailings per year, and the disc magnetic separator with a diameter of 500mm designed by Maanshan Mining Research Institute can obtain a yield of 5% to 6%. The rough concentrate with iron grade of 29% to 31% can be regrinded and re-selected to obtain a qualified concentrate with a yield of 2% and an iron grade of 60% to 63%. The project has been in operation for many years, with an annual recovery of nearly 40,000 tons of iron concentrate; using a shaking table to recover sulfur concentrate, the grade of which can reach more than 30%, and an annual recovery of 50,000 tons of sulfur concentrate.

2. Iron tailings are used as building materials

Currently, iron ore resources are embedded with fine particle size, and generally need to go through two-stage grinding, and a few three-stage grinding and sorting. Therefore, except for some coarse-grained tailings thrown out by pre-selection, most of the tailings discharged and stored in beneficiation have a particle size. It is relatively fine. Generally, the tailings particle size is less than 0.074mm, accounting for 50% to 70%. Only the tailings in the middle and lower reaches of the Yangtze River have coarser tailings. At the same time, the main mineral composition of iron tailings is similar to that of natural sand, and it is widely used in iron tailings concrete, iron tailings bricks, iron tailings thermal insulation wall materials, and iron tailings to prepare glass-ceramics and other building materials. It can not only reduce the accumulation of iron tailings caused by environmental pollution and land waste, but also replace some raw materials and save production costs.

Among them, the use of iron tailings to prepare glass-ceramics can develop high-performance, low-cost high-grade building decoration or industrial damage-resistant and corrosion-resistant materials, and improve the technical content and added value of tailings products. Therefore, scholars at home and abroad have carried out a series of researches on this issue in recent years. For example, Beijing University of Science and Technology used Damiao iron tailings and waste rock as the main raw materials to make tailings glass-ceramic granite; Shenyang Institute of Architecture and Engineering and Northeastern University jointly developed and utilized Weitoushan iron tailings and Xincheng gold mine tailings to add adjustment Oxides and appropriate crystal nucleating agents are used to form glass-ceramics for construction with diopside as the main crystal phase, and the amount of tailings can reach more than 65%.

3. Iron tailings are used for filling goaf

At present, mining methods such as caving method or ore retention method are mostly used in the underground mining process of iron mines in my country. Few people use the backfill mining method, which is mainly due to the fact that the price of iron ore in my country has been low in the past, and most of the surface exposed or shallow ore bodies are mined. In recent years, the mining depth of iron ore in my country has increased, and its proportion has become larger and larger. The value has been correctly appraised and the price has rebounded. Mining has formed a large number of goafs, which have brought serious safety hazards to the normal development of surrounding construction and mining work. Iron tailings are used as fillers in the goaf, which solves the land waste and environmental problems caused by the accumulation of iron tailings.

4. Iron tailings are used for ecological restoration

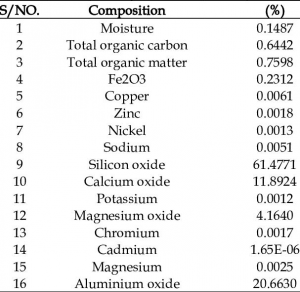

Although many countries have less people and more land, they attach great importance to land reclamation. For example, Germany, Canada, the United States, Russia, and Australia all attach great importance to the reclamation of tailings ponds. The land reclamation rate of mines has reached 80%. Iron tailings contain iron, zinc, copper, molybdenum, phosphorus and other trace elements required for plant growth. Using iron tailings to make fertilizers can improve soils and increase soil fertility.

As we all know, iron ore is a widely used and widely used strategic mineral resource belonging to the lifeline of social economy. Improving the resource utilization rate of iron tailings is of great significance for reducing the pressure on the utilization of existing mineral resources, turning waste into treasure, and ensuring the supply of iron resources. With the advancement of science and technology, the comprehensive utilization efficiency of iron tailings has been continuously improved. In order to build a resource-saving and environment-friendly society and achieve the goal of green mines, it is necessary to conduct more in-depth research on the comprehensive utilization of iron tailings.