Barite beneficiation belongs to non-metallic beneficiation and is a sulfate mineral. Its crystals are often thick plates, and the aggregates are granular or crystal clusters. Barite is insoluble in water and acid, non-toxic, non-magnetic, and can absorb X-rays and Y-rays. It is mainly used in petroleum, chemical, paint, filler and other industrial sectors, of which 80%-90% is used as a mud weighting agent in oil drilling. Barite is an important industrial mineral raw material for the preparation of barium and barium compounds.

Barite Mineral Types

6 types barite according to its mineral composition:

①Single mineral barite ore: The mineral contains BaSO480~98%, and there are few associated minerals;

②Quartz-barite ore: mainly composed of quartz and barite, the content of quartz is 30~50%, and the particle size of quartz inlaid affects the quality of the ore;

③ Fluorite-barite ore: barite and fluorite are the main minerals, and other associated minerals are quartz and calcite;

④Sulfide ore-barite ore: mainly composed of barite and iron sulfide, copper sulfide, lead sulfide, zinc sulfide, accompanied by quartz, fluorite and calcite;

⑤Iron ore-barite ore: mainly composed of barite and iron ore (magnetite, hematite, goethite), with associated quartz and calcite;

⑥ Clay or sandy barite ore: This type of ore contains different amounts of clay, rock debris, single mineral barite debris, etc.

Barite is a non-metallic mineral product with barium sulfate as the main component. It is the most widely distributed barium-containing mineral in nature and is produced in low-temperature hydrothermal veins. It is often symbiotic with quartz, fluorite, galena, iron ore, chalcopyrite, cinnabar, etc., and can also be produced in sedimentary rocks. Because of its large proportion in non-metallic minerals, the crystal aggregates are obvious.

Beneficiation Process Methods

1. Hand Separation

The choice of barite beneficiation method is affected by the type of ore, the nature of the original ore, the scale of the mine, and the use. Generally, residual ore is easy to select, so gravity separation method is preferred; sedimentary ore and hydrothermal ore associated with sulfide ore, fluorite, etc., in addition to gravity separation, flotation method is also used; barite flotation Commonly used anionic collectors: fatty acid salts, petroleum sulfonates or sulfates, etc.

Hand-selected: The color and density of barite and associated minerals are different, and massive barite is selected.

After the raw ore is mined, simple manual hand selection is a commonly used beneficiation method for many villagers to mine small mines. Some mines, due to their high geological grade and stable quality, can meet the export requirements of foreign trade after hand selection. For example, in Pancun Mine, Xiangzhou, Guangxi, the rich lump ore is selected by hand selection method. The hand-selecting method is simple and easy to implement, without any equipment, but the productivity is low and the resource waste is large.

2. Gravity separation

According to the density difference between barite and associated minerals, processes such as washing, desliming, screening, jigging, and shaking table are mostly used for residual ores.

The raw ore is washed, screened, crushed, graded and deslimed, and the concentrate of better quality can be obtained through the jig beneficiation process, and the product grade can reach more than 88%. The concentrate of Hengnan barite ore after gravity beneficiation can reach 92%. Local people wash the ore with the soil method, and each person can get 100kg of concentrate per day. The jaw crusher or impact crusher is generally used for crushing, and the roller crusher is generally used for fine crushing. The particle size of barite inlaid cloth is larger than 2mm, which can usually be sorted by heavy medium and jig. The maximum particle size of heavy media separation is 50mm, and the maximum particle size of wet and dry jigging is about 20mm. The particle size of the embedded cloth is less than 2mm, which can be sorted by a shaking table or a spiral classifier. Before the selection, the mud should be removed with a hydrocyclone to improve the selection effect.

The difference in surface physical and chemical properties between barite and associated minerals, commonly used in sedimentary barite ore and hydrothermal barite ore associated with sulfide ore, fluorite, etc. Flotation is an important way to deal with refractory barite resources such as low-grade ores, associated ores and tailings, and the process has good adaptability to various types of barite ores with complex inlays. It is also an effective way to recover fine-grained barite.

4. Magnetic Separation

According to the magnetic difference between barite and iron oxide minerals, it is mainly used to remove impurities of iron oxide minerals. When there is a significant difference in the magnetic properties of the minerals, the magnetic separation process can be used for separation. Barite is a non-magnetic mineral. When magnetic minerals (such as iron oxides) are the main gangue minerals, a magnetic separation process can be used to separate barite and gangue minerals. The resulting concentrate has a high BaSO4 content, which can be used as a requirement. Barite raw material for barium-based pharmaceuticals with very low iron content. Magnetic separation is often used to select pyrrhotite, magnetite, limonite and hematite.

barite processing plant Flow

The barite beneficiation method mainly adopts the gravity separation process, and the main equipment is a jig Concentrator.

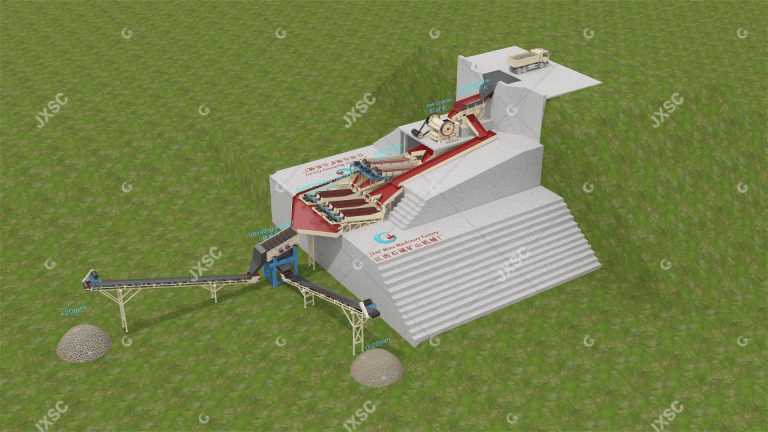

This setup is a barite processing plant, it is configured with a vibrating grizzly feeder, jaw crusher, log washer, spiral sand washer, vibrating screen, and belt conveyors.

The materials under the grizzly bar of the vibrating feeder are conveyed to 2 spiral sand washers through the material guide chute, the material above the grizzly bar is fed to the jaw crusher, the discharged material of the jaw crusher enters the 2 spiral log washers, and the spiral out materials is fed into 1 spiral sand washer, the overflow of the spiral ore washer is guided to the vibrating screen, and the discharging materials of the 3 spiral sand washers are all fed into the vibrating screen, and the vibrating screen sieve out 2 kinds of finished products with different particle sizes, 0-20mm and materials over 20mm.

The process has the advantages of simple equipment, good stability, no mineral processing agent, low cost, and less environmental pollution. JXSC has rich experience for design, control, and optimization of such a complex process for nearly 3 decades, with our solution, high recovery, high profit and low cyanide concentrations can be achieved simultaneously.